Rapid 3D Printing

for Microfluidics

Accelerating Innovation with Precision & Speed

Overview

Precision Fabrication from Nano to Macro

HiComp combines multiple 3D printing technologies to meet the diverse structural, resolution, and material needs of microfluidic innovation. From submicron-resolution biochips to millimeter-scale cartridge molds, we support researchers and product developers from concept to production.

Facilities

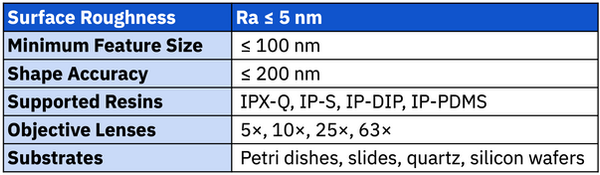

Two-Photon Polymerization (TPP) 3D Printer

Model: Nanoscribe Quantum X bio

Principle: Uses a 780 nm laser to locally polymerize light-sensitive resin for ultra-high precision 3D fabrication.

Applications: Superlenses, microneedles, cell culture scaffolds, microfluidic molds

Max Build Area: 50 × 50 mm

DLP Projection Micro 3D Printer

Model: BMF S230

Principle: Uses digital light projection for high-resolution, rapid prototyping of microscale structures.

Applications: Microneedle arrays, PDMS chip molds, microchannel test structures

Max Build Area: 50 × 50 × 50 mm

Key Applications in Microfluidics

PDMS mold fabrication for complex microchannel designs

Create reusable or disposable molds with intricate 3D geometries, bypassing the limitations of traditional lithography.

High-resolution microneedle arrays

Fabricate sharp, mechanically robust microneedles with fine feature details for transdermal delivery or sampling.

Custom optical or sensor interfaces

Tailor-make interfaces for integrating micro-optics, electrodes, or embedded detection units into microfluidic systems.

Rapid prototyping of structural components

Accelerate iteration cycles for chip housings, cartridge frames, and functional test fixtures.

Integrated fluidic connectors and adapters

Print complex fittings with precise tolerances for plug-and-play fluidic integration.

Why Choose 3D Printed Microfluidics?

1

Multi-platform capabilitie

From sub-100 nm to millimeter-scale fabrication

2

Material flexibility

Compatible with biocompatible, optical, and elastomer-compatible resins

3

Custom development

Print optimization, size tuning, and integration support

4

Microfluidic expertise

Designed for fluid sealing, flow paths, and downstream assembly

5

Rapid turnaround

Prototypes ready within 48 hours

Applications

• Microneedle arrays and molds

• PDMS microfluidic chip molds

• Cell culture microenvironments

• Optical metasurfaces and micro-lens arrays

• Microchannel networks and integrated fittings