-

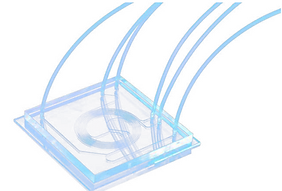

HiComp delivers production-grade PDMS devices with a clean finish, precise thickness control, and injection molding level quality.

-

Support organ-on-chip, organoids, cell culture, diagnostics, liquid biopsy, and drug discovery with speed and industrial-scale yield.

Applications

Process flow -Lab vs. HiComp at Scale

Typical Lab Setup

HiComp Production

Manual weigh & hand-mix; variable degassing

Metered mixing and controlled vacuum degassing in dedicated equipment for bubble free bulk PDMS and batch-to-batch consistency.

2.PDMS Mixing

4.Bonding

6.Assembly

Benchtop tubing; manual assembly

Single-piece plasma bonding by hand

Batch bonding in fixtures and high yield.

Documented assembly (tubing, membranes, electrodes) or cartridge integration for high-volume packaging.

1.Master Mold

SU-8 photoresist on wafer; open tool; limited lifetime

Mother mold Tooling by using 3D printing, CNC, SU-8, and silicon etch; long-life resin master for batch fabrication.

3.Casting / Molding

Open cast on wafer; thickness & flatness vary

Closed-mold PDMS molding with calibrated pressure for thickness, planarity, and surface finish control.

5.Ports & Reservoirs

Manual punch/drill; debris & misalignment risk

Molded-in ports/reservoirs (no punching) or precision drilling with capture & clean protocols.

When to use which

-

Prototype & small batches (1–100 pcs/order): lab-style or hybrid for speed.

-

Pilot/bridge (100–500 pcs/order or <500 pcs/month): hybrid with selected closed-mold steps to boost yield.

-

High volume (≥500 pcs/month): HiComp closed-mold production for repeatability, cost, and scale.

HiComp PDMS Capabilities

Geometry & Features

Minimum channel width: ≥ 2 µm

Channel depth tolerance: ±5%

Channel aspect ratio: up to 10:1

Minimum through-hole diameter: 0.30 mm

Maximum chip size: up to 300 mm × 300 mm

QC& Logistics

-

Cleanroom: ISO 7 protocols

-

Particle control: microscopic inspection; debris-free in critical areas

-

Lead times: 2–3 weeks after design confirmation (expedites available)

-

MOQ: no strict MOQ; pricing improves with batch size

-

Maximum monthly capacity: up to 80,000 pcs/month

-

Deliverables: bare chips, chips with pre-assembled tubing,

or fully integrated cartridge assemblies

Layers

-

Layer count: 2–8 layers

-

Alignment accuracy (typical): 0.10 mm (tighter available on request)

-

Thickness tolerance: up to ±5 µm (design-dependent)

-

Flatness: as low as 2 µm, maintained via closed-mold planarity controls

-

Color/tinting: clear (default) or tinted/colored PDMS

Bonding & Integration

-

Bonding options: bubble-free glass/PDMS and PDMS/PDMS bonding

-

Bond strength: > 60 psi

-

Temporary/reversible bonding: available on request

-

Integrated features: molded-in through-holes/reservoirs

-

Membranes & electrodes: bonded membranes; embedded electrodes supported

Why Choose Us

Integrated Mold

Closed mold, NOT SU-8 wafers.

Precise Molding

Molded, NOT casted.

Scalable Pipeline

By technicians, NOT scientists.

ISO 7

Cleanroom

ISO 13485

Certified

FDA

Registered

1M+ PDMS

Chips Delivered

Trusted by

Global Leaders